Perovskite light-emitting diodes are moving from lab curiosity to serious contenders for the bulbs in your ceiling, the strip behind your TV, and the pixels in your phone. They promise light that is cheaper, brighter, and more flexible than today’s LEDs, with a smaller environmental footprint if engineers can solve a few stubborn problems. The race is now on to turn that promise into hardware that can replace nearly every light in your house.

Researchers are pushing perovskite devices to higher efficiency, longer lifetimes, and safer chemistry, while companies test early products in wearables and smart home gadgets. The data and prototypes point in the same direction: if current trends hold, perovskite LEDs will not stay confined to research papers for long.

What makes perovskite LEDs different

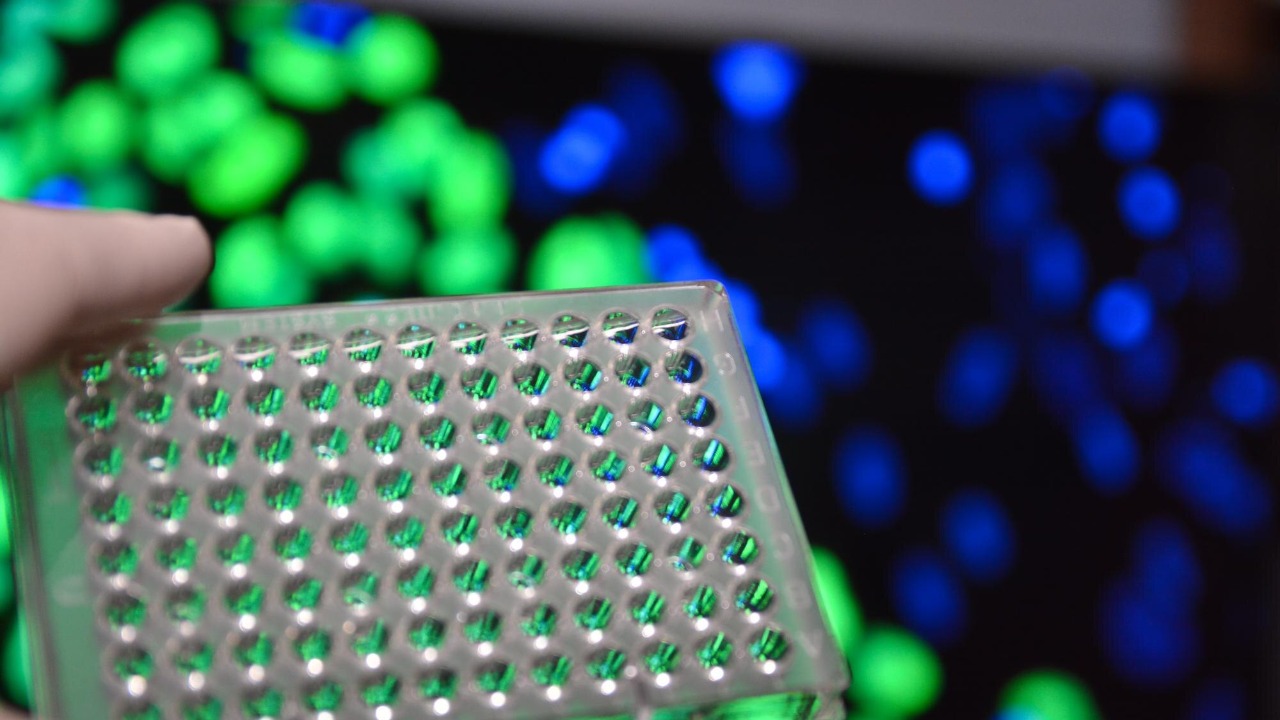

At the heart of this shift is the material itself, a crystal structure known as Perovskite that can be tuned to act as a very efficient light emitter. In detailed work on sustainable PeLEDs, Jan and other researchers describe how these compounds absorb and release energy in a way that rivals or beats conventional semiconductors. Perovskite light emitting diodes, often shortened to PeLEDs, can reach high brightness at low voltage, which is exactly what home lighting and displays need.

Color is also remarkably easy to adjust, from deep blue to warm white, by changing the material mix or layer thickness. One analysis of Perovskite light emitting points out that this tunable bandgap is built into the chemistry, not bolted on through filters or extra layers. That flexibility is why engineers see PeLEDs as frontrunner candidates for the next generation of lighting and displays, rather than a niche add on.

Cheaper, brighter, and ready for your living room

Cost is one of the strongest arguments for swapping your current bulbs for perovskite based ones. A study on deep blue devices reports that the material cost for manufacturing perovskite LEDs is below US$3 per gram, while the material cost for comparable commercial LEDs exceeds US$20 per gram. That kind of gap gives manufacturers room to cut prices or pack in more performance without making lamps unaffordable.

Brightness and efficiency also look promising for home use. Reporting on why Why Perovskite devices Might Soon Replace Every Light in Your Home highlights that they can be Cheaper to produce while matching or beating the luminous output of current LEDs. Researchers there describe how careful control of the crystal structure and interfaces reduces wasted energy, so more of the power you pay for shows up as useful light instead of heat.

From lab benches to Swedish living rooms

The shift from theory to real homes is already under way in Scandinavia. Mar reports that Now Swedish researchers perovskite LEDs could replace your home lights, pointing to reduced cost, high efficiency, and the potential for large scale production. Their work links the same materials to applications that range from living room lamps to lighting on the International Space Station, underscoring how wide the design space has become.

A companion report on how LEDs of perovskite are emerging as an alternative notes that these devices can light homes and electronic devices with the same basic stack. In practice, that means the bulb over your kitchen table, the backlight in your laptop, and the status light on your router could all rely on one shared manufacturing ecosystem, which helps drive down costs and speed up adoption.

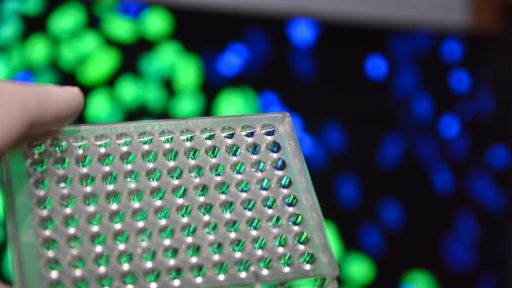

How they are made and why that matters

Perovskite LEDs are not only different in what they are made of, but also in how they are made. One report describes Manufacturing LED lights from gasses, using the bipolar electronic properties of the perovskite structure to grow thin films that can be tuned to emit specific colors. Gas based and solution based methods allow large areas to be coated at low temperatures, which opens the door to roll to roll processing on flexible substrates.

Indian scientists at CeNS, Bengaluru, have taken a different route, focusing on stability and composition. A detailed note on Perovskite Based LEDs explains how Context from Indian teams in Bengaluru uses a class of materials that can act as direct bandgap semiconductors used in LEDs, and how interface engineering can extend device life. By refining both the chemistry and the stack, they aim to move PeLEDs from hundreds of hours of operation toward the tens of thousands that home lighting demands.

Flexibility, wearables, and CES showpieces

One of the most striking differences between perovskite LEDs and the bulbs in your ceiling is how bendable they can be. A review of flexible perovskite devices notes that advantages of these devices include compatibility with polymers that possess excellent flexibility, along with strong optoelectronic performance. That combination is tailor made for smartwatches, rollable displays, and light strips that you can wrap around furniture.

The trend is already visible on the trade show floor. At the Consumer Electronics Show, a press statement from LAS VEGAS explained how BiLight Shines at CES 2026 as flexible perovskite PV took center stage in the Consumer Electronics Show PV + Space application ecosystem. The same thin, flexible approach that works for solar sheets can also support thin PeLED panels for accent lighting, under cabinet strips, or even glowing wallpaper that changes color on command.